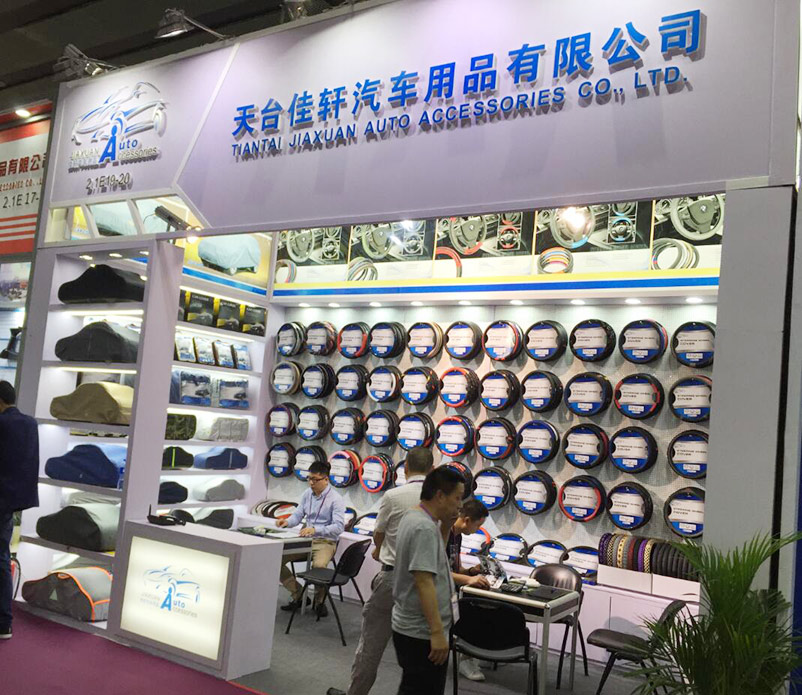

As automotive design becomes increasingly diverse, brands look for production partners that can translate concepts into functional, market-ready products. A professional accessories factory and accessories manufacturer plays an essential role in this process, supporting both established companies and emerging labels with high-quality car interior components such as steering wheel covers, seat cushions, side mirror protectors, and car mats. The preference of many brands to collaborate with experienced manufacturers is based on practical, measurable benefits that influence efficiency, cost control, and long-term competitiveness.

Access to Specialized Production Capabilities

Automotive accessories require a combination of precision and durability that few general factories can provide. An accessories manufacturer usually operates advanced production lines equipped with automated cutting machines, high-speed sewing systems, and surface treatment facilities. These capabilities allow consistent results, even when handling different materials like leather, fabric, and synthetic polymers.

For instance, producing snowproof mirror covers or water-resistant car seats involves more than just stitching—coating technology, pattern precision, and quality control systems all affect performance. Partnering with a factory that has specialized equipment and trained technicians ensures that every product meets required functional standards. Brands appreciate that such partnerships reduce rework rates, improve production predictability, and maintain a uniform appearance across their product range.

Support for Customization and Product Development

One of the major reasons brands turn to experienced factories is design flexibility. Automotive accessories must reflect a brand’s unique identity while maintaining compatibility with a variety of vehicle models. A professional factory typically provides design assistance, material recommendations, and prototype development services.

This collaborative approach allows brands to test product concepts quickly. Whether it’s developing a new series of steering wheel covers with improved grip or seat belt pads featuring customized patterns, manufacturers can adjust designs efficiently to align with market preferences. This adaptability not only speeds up the product launch cycle but also enables brands to offer more choices without maintaining their own production facilities.

Consistent Quality Assurance and Testing Standards

Maintaining product consistency across large production volumes is a challenge that experienced manufacturers handle through structured quality control systems. Before accessories reach distributors or end users, they go through multiple inspection stages—checking dimensions, color accuracy, stitching strength, and resistance to wear.

Some factories perform environmental testing to simulate long-term use. For example, products such as car mats or seat covers are tested for abrasion, temperature resistance, and flexibility. These internal quality checks give brands confidence that the products they distribute meet performance expectations. A dependable quality system reduces after-sales issues and strengthens customer trust, which is critical in competitive markets.

Cost Efficiency and Supply Chain Stability

Outsourcing to an accessories factory helps brands manage costs without compromising quality. Large-scale manufacturers purchase raw materials in bulk and operate with established logistics systems, which lower unit costs for components. This efficiency extends to packaging and delivery, where standardized procedures ensure smooth export to global markets.

Additionally, factories often maintain long-term relationships with suppliers of fabrics, coatings, and hardware. For brands operating on tight schedules, this supply chain reliability can determine whether a product reaches retail shelves on time.

Compliance With Industry and Environmental Standards

Brands today face increasing pressure to meet both performance and environmental standards. Accessories manufacturers stay informed about regional and international regulations, such as restrictions on certain chemicals or recycling requirements for automotive materials. By integrating compliance into their production process, manufacturers help brands avoid potential legal and market risks.

Environmentally conscious production methods—such as using water-based adhesives, recyclable materials, or low-emission manufacturing systems—align with global trends toward sustainability. When brands collaborate with manufacturers already implementing these practices, they can promote environmentally responsible products without needing to invest heavily in new facilities.

Scalability and Timely Production Adjustments

Market demand for automotive accessories can fluctuate based on seasons or new vehicle launches. A factory’s ability to adjust production volumes efficiently is one of the main reasons brands prefer external manufacturing partnerships. When a particular product line—such as winter mirror covers or seat cushions—experiences higher demand, factories can reallocate resources and increase capacity quickly.

Scalable production also supports limited-edition or promotional runs. Brands can introduce new styles or materials temporarily without long-term investment risks. Once demand stabilizes, production schedules can return to normal levels, maintaining both flexibility and profitability.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch عربى

عربى